Although no two printers are exactly the same, there are usually a few issues that all FDM printers have in common. In this series of articles, we will explore some of the most common troubleshooting issues that FDM printers experience.

At the heart of an FDM printer's printhead are the extruder gears. These gears perform the critical function of pulling filament from the spool and forcing it down into the hot end and through the nozzle. The gears work by grabbing filament with the teeth of the gears, and once dialed in, they are generally quite reliable. However they are not entirely maintenance free and occasionally, the gears can slip, causing a clicking sound that can alarm printer owners. Below are a few easy steps to fix this issue.

Fix 1: Inspect for and Fix a Blocked Nozzle

The job of the gears in the printhead is to push filament through the hot end. Usually this is no big deal, but if a hot end becomes blocked, then the gears can be prevented from doing their job. The clog will need to be cleared before printing can resume.

To clear a blocked nozzle, the hot end must first be heated using the printer's internal controls. Without first heating the nozzle, the filament can remain cold and hard and the nozzle will be difficult to remove. Once the filament has come up to temperature, the nozzle can be unscrewed from the hot end. Most nozzles can be removed with a 5.5mm socket, but be prepared to use a different size if you're not sure what size your nozzle is. Exercise caution when doing this, since, of course, the nozzle will be extremely hot. With the nozzle removed, carefully run a piece of brass wire (guitar strings can work well) through the nozzle to clear the blockage.

Fix 2: Set Z-Height

Another way in which the gears of the printer can be blocked is by the printer's nozzle coming too close to the bed. When this occurs, there may be insufficient room for the filament to exit the nozzle. Since the gears aren't strong enough to push the filament through the bed (thank goodness), they skip instead.

The fix for this is to simply raise the z-height of your 3D printer until it reaches the proper height as recommended by your printer manufacturer. This process is usually relatively straightforward and it is likely that guides exist for how to do this for your exact printer!

Fix 3: Level Your Print Bed

Just as a low nozzle height can block filament from becoming extruded, so too can an uneven bed. Even if z-height is set correctly for one area of a build surface, a bed can become unlevel and higher in other areas. As with setting z-height height, it is likely that a procedure for leveling your particular printer's bed is available online (assuming your printer does not already come with an auto-leveling function).

Fix 4: Adjust Gear Spring Tension

The gears in most printheads are held in position, pressed against the filament by a gear spring. If this spring becomes loosened or untightened the gears will only be loosely pressed against the filament and will not be able to grip it effectively. As a result, even if the path for the filament is clear, the extruders will slip and click and filament will not be extruded.

Gear spring tension can usually be adjusted by a thumb screw, near the top of the printhead. This screw can be identified easily because it passes through a spring. Tightening the screw causes the spring to press the gears more firmly against the filament, which should fix the issue!

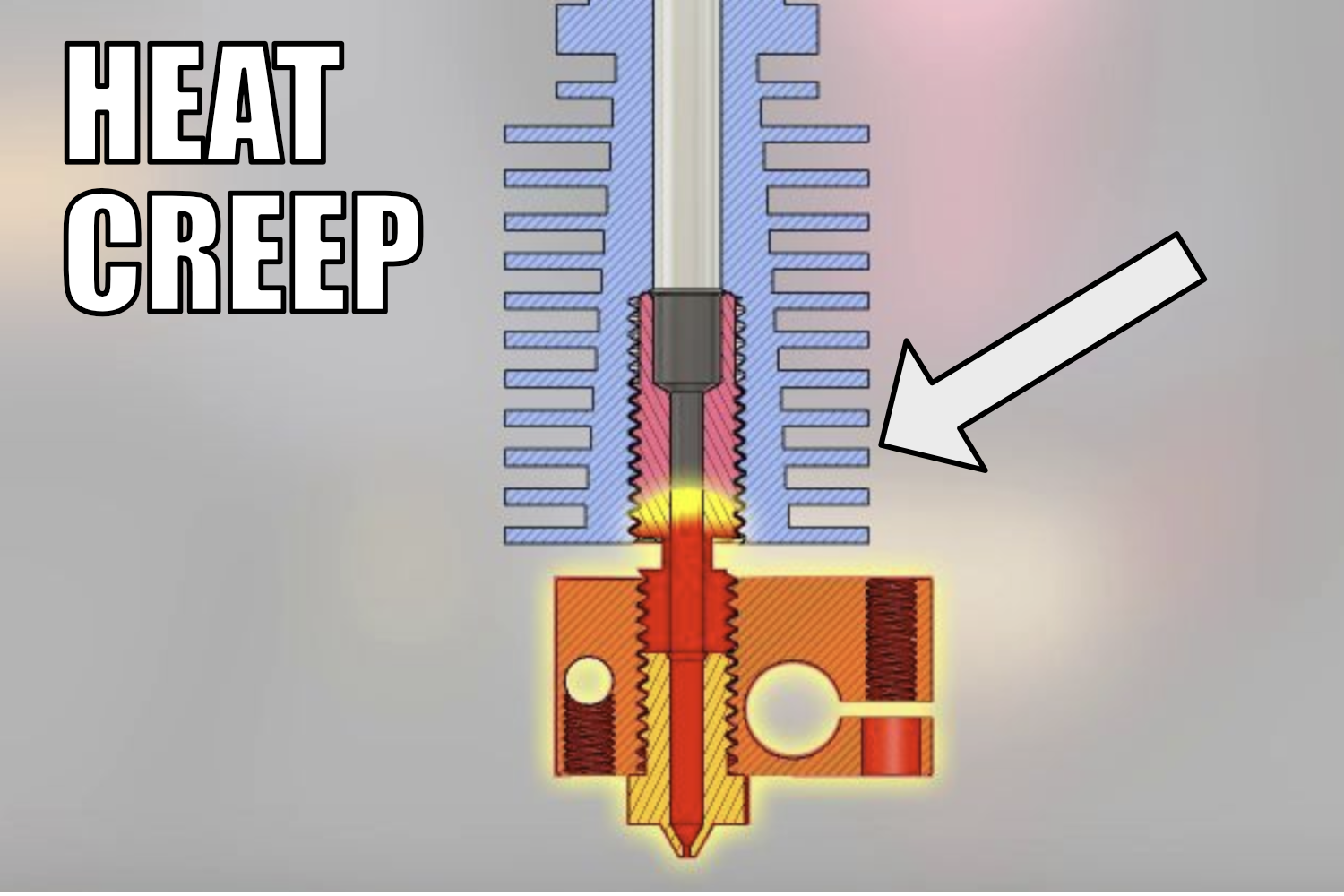

Fix 5: Increase Nozzle Temperature

Nozzle orifices are typically much smaller than the filament which will be pushed through them. The only way for filament to exit the nozzle is for it to become melted by the high nozzle temperatures, and then forced through the orifice in the melted state. If temperatures are not high enough to melt the filament, then the extruder gears will push solid, unmelted filament against the equally solid nozzle body. In this conflict, the nozzle usually wins, and the filament will be stopped and the gears will slip.

The fix for this is to ensure that nozzle temperatures are always properly set for your filament of choice. particular attention should be paid to this when switching from one filament to another which is printed at a higher temperature. Luckily, this issue can usually be caught and detected early in the print process, meaning that even when it is missed, it can be quickly addressed, and printing can resume without issue!