The ORIGINAL Threaded Peg Board.

Thread boards made their debut in early 2023, pioneering the concept of 3D printable peg boards with threaded pegs that securely fasten components.

Thread Boards is one of the most practical 3D printable designs available. Its versatility is unmatched. But why 3D print a peg board in the first place? The answer to this question is customizability. There is so much you can do with Thread Boards. It is infinitely expandable, has tons of attachments, and you can also print it in any color to perfectly match your aesthetics.

Table of Contents (jump to location):

- Basic Assembly Example

- Mounting with Command Strips

- Laptop Computer Stand

- Desktop Monitor Stand

- Floating Shelves

- Wall Mounted Marble Track

- Suggested Print Settings

- Parts List

Thread Boards Assembly Example:

The diagram below shows the basic assembly of Thread Boards:

As you can see in the diagram above, assembly is fairly straight forward. However, these is one very important thing you must consider when connecting two threaded boards together: you need to use a "narrow shaft" screw. Narrow shaft screws allow to threaded components to securely attach and clamp together.

You can use Thread Boards to make tons of custom things. For example, you can use Thread Boards to create a simple laptop stand to use when you aren't feeling well, or simply want to relax.

The diagram below shows the basic assembly of a laptop stand. It's important to note that you can customize the size to fit your needs and requirements. For example, if you want it to be extra wide, you can connect three Thread Boards together instead of two. You can also attach additional Thread Boards to the leg to make it taller. To make it sturdier, simply add more 1x? plates (non-threaded).

Mounting with Command Strips:

If you don't want to screw Thread Boards directly into your wall, you can mount the boards with Command Strip adapters. Because the Command Strip adapters are threaded, and the thread boards are also threaded, it is suggested to use narrow shaft screws. This allows the two threaded components to secure tightly.

Laptop Computer Stand:

Another interesting thing you can do with Thread Boards is create a desktop shelf/monitor stand with an actual piece of wooden board. This can be used in place of a standing desk or computer monitor stand and the wooden board gives it extra strength and aesthetics qualities. The best part is that you can use practically any piece of wood and you can attach any Thread Boards accessory to it.

Desktop Monitor Stand:

The basic assembly diagram of the desktop shelf is shown below:

Floating Shelves:

To attach the floating shelves to Thread Boards, it's very important to remember to use the 'narrow shaft screws' because they allow for the connection of two threaded components to securely attach together.

In addition to practical applications, you can also have some fun with Thread Boards. Included in the accessories is everything you need to create amazing marble tracks. You, or your kids, can spend hours creating these. At the end of this YouTube video, you can see the marble machine in action:

Wall Mounted Marble Track:

The marble track features an automatic spiral lift that is powered by a N20 DC motor and speed controller. The parts list/basic assembly diagram is shown below:

Share Your Thread Boards Creations On Social Media

I love seeing what you all are creating. Share your creations on Instagram using the hashtag #ThreadBoards or #3DPrintedThreadBoards

Suggested Print Settings

99% of the Thread Boards files can be printed without supports using default slicer settings. Here are the settings I typically use:

- Layer height: 0.28mm

- Infill: 15% grid, cubic, or gyroid infill

- Wall line count: 2-4 lines

- Suggested Materials: PLA, PETG, ABS, ect

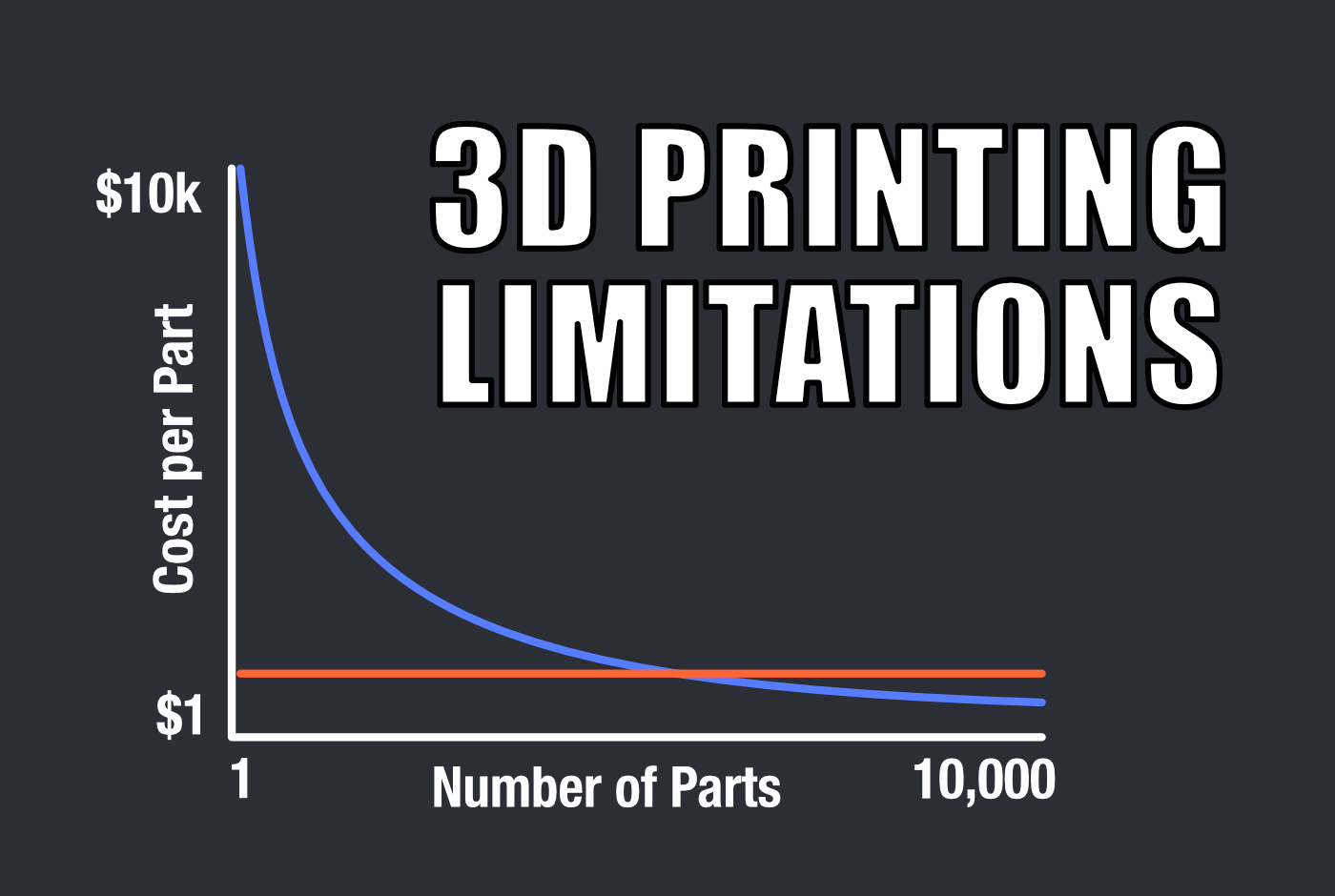

Print Times:

The printing time depends greatly on the printer. Bambu Lab printers can produce a 7x9 board in 2.5 hours. Conversely, a traditional bed slinger would take approximately 7 hours to print the same 7x9 board. These times are both estimated assuming a layer height of 0.28mm

Strength Considerations:

It's important to note that print results may vary depending on your specific 3D printer, slicer, and numerous other factors. If you plan on using Thread Boards to hold heavier objects, I highly suggest increasing the wall line count to at least 4 lines and the infill to 20-30%.

Print Orientation:

The Thread Boards should be printed lying flat, and the screws should be printed with the threads pointing upwards. No supports are needed for the screws.

Parts List

In your downloads, the files are organized into two folders: 'Start Here' and 'All Files'. The STLs in the 'Start Here' folder are shown below. These are the fundamental STLs needed to make a basic Thread Boards setup. There are two different board sizes to choose from:

Start Here:

Accessories (Not all shown):

Rounded Containers:

Square Containers:

Other Accessories:

Marble Run STLs:

Letters:

Threaded Screws (Thread 12mm Head):

Threaded Boards (8mm)

About Thread Boards:

Introduced in early 2023, Thread boards represent the first 3D printable peg board system to utilize threaded pegs for reliable component attachment.

Happy printing!

-Steven