3MF: A next generation 3D model file format that describes model surfaces recursively, able to make more detailed curved surfaces. Unit-defined, color capable. Growing adoption within the community but is behind STL as the file format leader. Must be sliced before 3D printing.

ABS: Acrylonitrile Butadiene Styrene. One of the oldest established filaments, actually the same plastic used in LEGO®. Prints at 210-250C nozzle temp, ~100C bed temp, and 60C chamber temp. Releases toxic fumes, but is highly temperature resistant plastic in the hobbyist range of prices.

ASA: Acrylic Styrene Acrylonitrile. An alternative blend most commonly related to ABS. Impact, temperature, and UV resistant. Prints at 220-245C nozzle temp, 90-110C bed temp, and 60C chamber temps. Releases toxic fumes as well, but not as bad as ABS.

Belts: The part of the printer responsible for translating rotational motion of the stepper motor spindles into fast linear motion on the gantry. Connected to the stepper by a gear.

Brim/Raft/Skirt: Types of printer surface / bed adhesion tools used to help a part stay “glued” to the printer bed, to prevent prints from breaking off mid-print. Rafts use the most material but ensure the part will stick and is level when printed. Brims add a “brim” around the base layer of the part to add additional surface area for the part to adhere to the bed. Skirts act as a priming region off of the part to prepare the nozzle for printing. Skirts use the least amount of material.

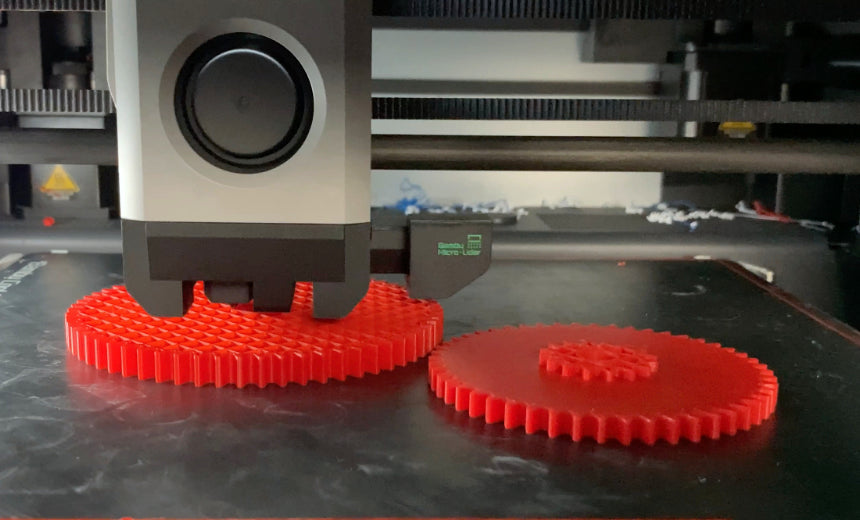

Build Plate: The part of the printer that holds the printed part down while a print occurs. Has a special plastic-adhesive surface, most commonly PEI, but can be glass, garolite, or others. Might have a detachable sheet for ease of use. Typically is heated using a bed heater element.

CAD/CAM: Computer Aided Design or Computer Aided Manufacturing. Software like SolidWorks, Fusion 360, and Onshape are common software CAD/CAM suites that help users design and model parts. CAM simulates manufacturing by CNC to make parts.

Drive Gear: A metal wheel with sharp teeth found in the extruder of a printer. Larger drive gears seem to perform better for more consistent extrusion and printing.

Extruder: The part of the printer that pushes plastic. This is normally done using a stepper motor that powers a drive gear with teeth that bite and push plastic as the gear rotates. Can be single or dual drive, the latter of which is generally better. Using an idler, the user can control how much force the gears press into the filament.

Filament: The raw, spooled plastic material that is consumed when 3D printing. Comes in 1.75 and 2.85mm diameters, and found in many kinds of blends (see filament section for more detail). Typically sold in 2.2lb or 1kg spools.

Flow Rate: Slicer Setting and printer adjustable setting set in % that governs how much filament is being extruded. Higher flow rate = more filament extruded, and vice versa. Ideal flow rate is a function of filament type, diameter, extruder type, and temperature.

Gantry: The frame of the 3D printer. Typically made of low-cost aluminum extrusions, the gantry holds most of the components on the printer. It should be rigid and have elements on them that move in the coordinate axes (X, Y and Z).

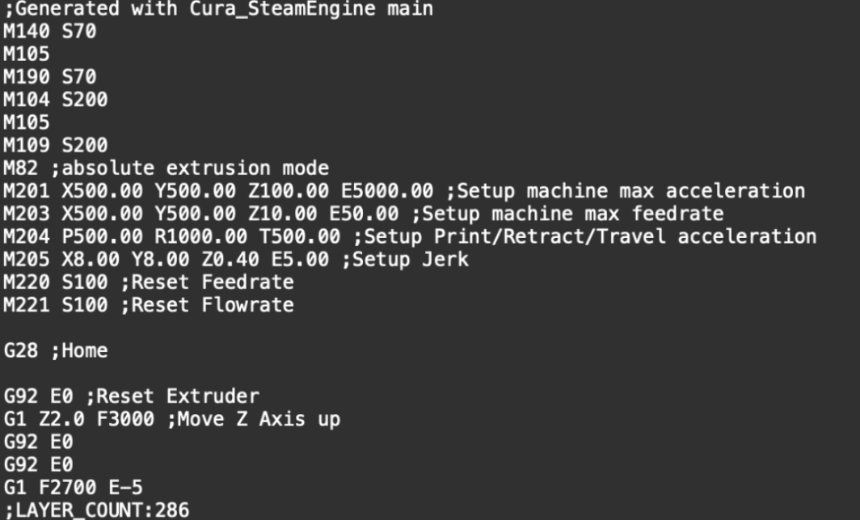

GCODE: Machine-level, line-by-line instruction sets that are generated by slicers. GCODE runs directly on 3D printers. A universal GCODE standard exists that allows slicers to communicate position, temperature, homing, and other routines to printers in a consistent way.

Hot end: The part of the printer that gets hot to melt filament. Typically has a heater block which has a heating element and thermistor for thermostatic control, a nozzle to push filament through, and a heartbreak that prevents heat from traveling up into the rest of the printer which could cause clogs. A heatsink and fan are found on the opposite end of the heatbreak to further dissipate heat-- but this region of the printer is considered the “cold side”.

Idler: An compression device on the extruder that users adjust to fix filament drive gear tension.

Infill Pattern %: Slicer setting that defines the printed pattern within print’s internal volume. Does not contribute that much towards final part strength, but helps with maintaining part shape, wall impact strength. There are many possible patterns available (over 15). Infill % defines how much infill density there is. Higher %, the more filled in the internals are. >20 % infill density does not provide any significant additional strength.

Layer Height: Slicer setting that defines how tall each printed layer in the Z dimension is. Smaller layer heights may improve fine detail resolution, but takes longer time and have lower part strength (more layer interfaces is weaker). Taller layer heights reduce fine detail resolution, but take shorter time to print and have higher part strength.

Lead Screw: The part of the printer responsible for translating rotational motion of the stepper motor spindle into slower linear motion on the gantry. Connected to the stepper by a coupler, though custom steppers with integrated lead screws exist.

Mainboard: The electronic controller found inside the printer that coordinates heating, cooling, motion, homing, and printing. Controller/mainboards are the heart/brain of the 3D printer and can be upgraded for more features. All electronics of the printer begin and end at the mainboard.

Overhangs: Regions of a printed part that are “larger” than the layer below them- when the part is “hanging” over itself. Most printers with good cooling can handle 45 degree overhangs with no supports, but this depends on the material as well.

PA-CF: Polyamide (Nylon) with carbon fiber fill. Carbon fiber adds increased rigidity and works well together with the flexibility and impact resistance of nylon to make better parts. Prints at same conditions as normal PA, but requires printers with abrasion-resistant parts like hardened nozzles, heat-breaks, and liners.

PA: Polyamide AKA Nylon. A tough filament with slight flexibility and high impact resistance. Prints at 220-250C nozzle temp, 70-90C bed temp, and 50-60C chamber temp. Highly sensitive to humidity, and needs to be dry. Needs special bed adhesive and heated chamber to print properly as it warps easily.

Perimeters/Shells: Slicer setting that defines the number of printed walls within the part. The more perimeters/shells/walls = stronger parts, as part strength is directly correlated to wall strength. However, more perimeters takes more time to print.

PETG: Polyethylene Terephthalate Glycol. A step up from PLA with more thermal resistance and impact resistance. Prints at ~250C nozzle temp, ~80C bed temp, and ambient chamber temperature (lower the better). Known to ooze and string a bit more, and sensitive to humidity, store in dry environments.

PLA: Polylactic Acid. Arguably the most reliable printer filament available. Prints at 190-225C nozzle temp, 35-60C bed temp, and ambient chamber temperature (lower the better). Low thermal resistance, high rigidity, and low cost. Made from corn! Sensitive to humidity, store in dry environments.

Print temperatures: Plastic filaments have optimal printer temperatures for print quality, speed, and outcome. There are three temperatures to be aware of: hotend/nozzle temp, build plate temp, and build chamber temp. Some filaments require special storage conditions as well.

Printhead: The part of the printer that extrudes plastic and moves along an axis (or 2, depending on the architecture). At least includes a hot end, nozzle, heartbreak, heatsink, and fans-- but can have more (extruder, toolchanger, auto bed leveling devices, filament sensor, LEDs, and more).

Rails/smooth Rods/rollers: The part of the printer that constrains motion to singular axes. Linear rails are the most expensive but precise option. Smooth rods are cheaper but work well, and roller wheels are the cheapest.

Retraction: Slicer Setting that defines how far back filament is pulled in millimeters before a non-printing movement. More retraction = less potential oozing, but higher likelihood of clogs and potentially more print defects. Bowden-extruders will need more retraction compared to direct-drive extruders.

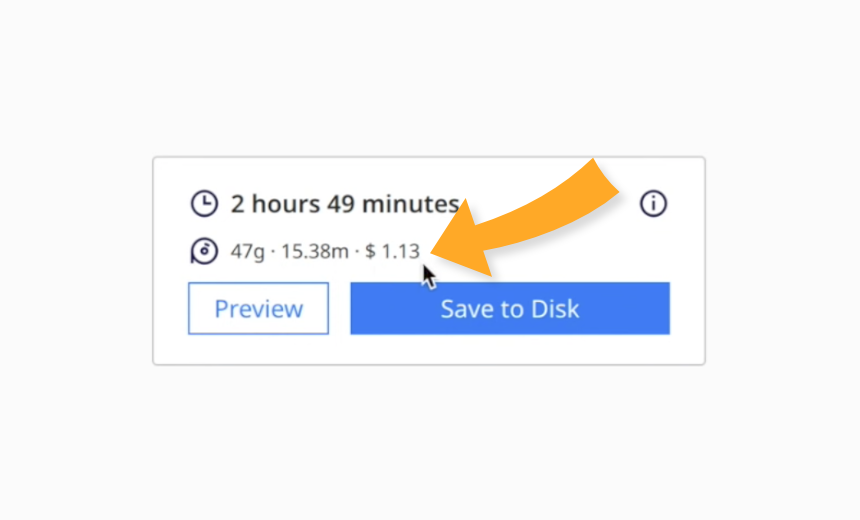

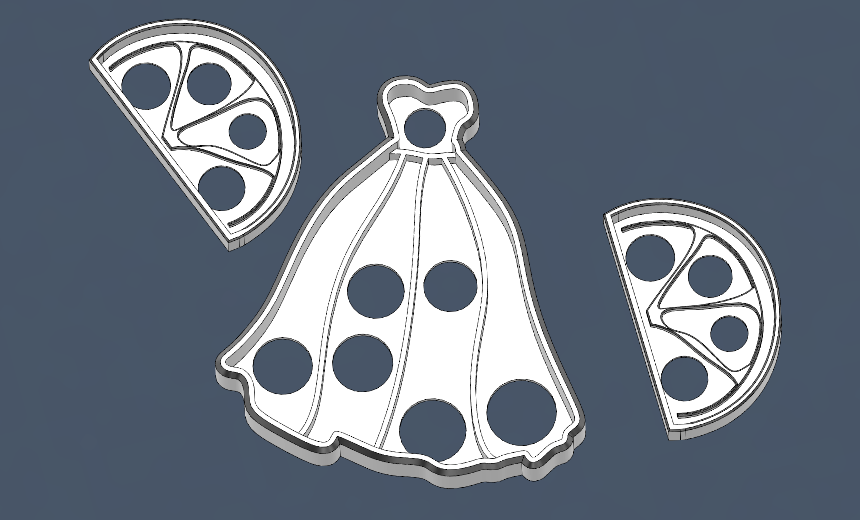

Slicer: Software that converts an STL model into 3D printer GCODE instructions following user specified slicing settings. Popular slicer options includes Cura, PrusaSlicer, Simplify3D, and Slic3r.

Slicing Settings / Print Settings: Settings within a slicer that define how a model will be printed-- layer heights, temperatures, speed, movement patterns, infill, and more. These settings have a major impact on print speed, quality, part strength, and other attributes beyond impacts by filament type and printer alone.

Stepper Motors: The part of the printer that converts electrical energy and signals into rotational power. Controls gantry motion and extruder. Popular variants include the NEMA 17 or NEMA 14, though “pancake” variants exist that are shorter, provide less power, but are smaller form factor and lighter.

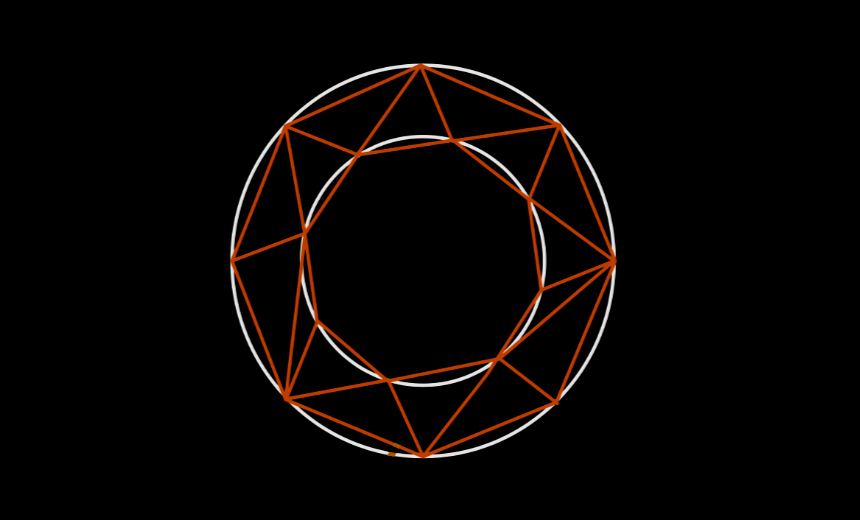

STL: 3D model file format that describes model surfaces as many flat, tessellated triangles. Can be binary or ASCII format. Unit-less, colorless, but widely used for distributing 3D files. Must be sliced before 3D printing.

Supports: Non-part regions that are printed to help printers print overhang or “islands” on the part. Density, support pattern, support-part interface can be controlled in slicer settings. More dense supports are stronger and less likely to fail but use more material. Interfacial regions that are closer to the part will support the part better leading to better part quality and less failures, but are more difficult to remove.

Z-hop: Toggle-able slicer setting that tells the printer to “hop” a set Z distance in mm when making non-printing movements, to avoid crashing into printed regions.

Z-Seam: Slicer Setting that defines where previous layers stop and new layers begin. There is a visible mark where the seams are so plan accordingly to minimize the seam defect on your part. Playing with retractions, temps, and flow can minimize seam artifact appearance on your part.