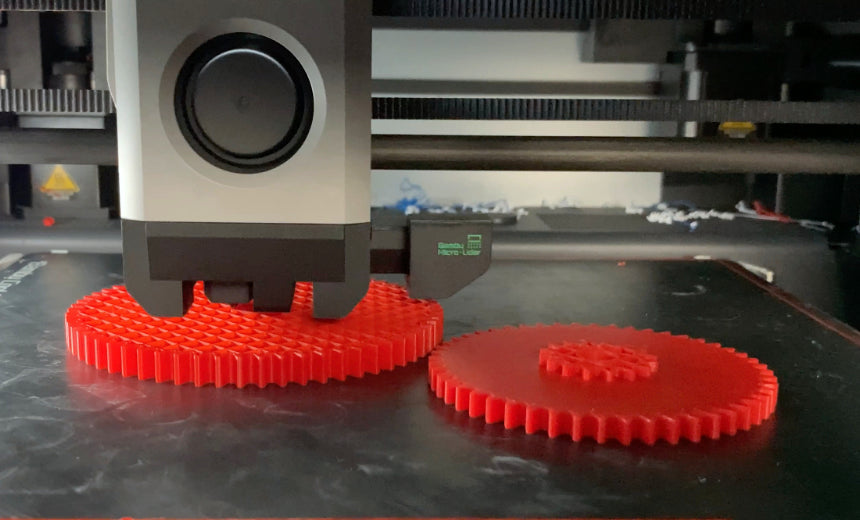

In the world of 3D printing, an issue that both beginners and seasoned veterans often encounter is poor bed adhesion. A lack of bed adhesion can cause your print to warp upwards, making it dimensionally inaccurate, sometimes ruining an otherwise perfect print. In other cases, it can cause a print to fail entirely, leaving you with a mess of plastic spaghetti. Fortunately, there are a few ways that this can be prevented.

The problem causing poor bed adhesion is almost always an unleveled bed. Although this is a boring process, it is important to maintain the perfect distance between your bed and the nozzle. Too high, and the plastic won’t stick to the top bed - too low, and you will suffer from “elephant’s foot” which can cause your first layer to be significantly bigger than the rest, sticking out a bit. You can level your bed by moving the nozzle to each of the four corners, lowering it until the z-endstop is triggered, and then trying to run a folded piece of paper between the bed and the nozzle. Continue adjusting each of the knobs until you feel a slight amount of friction when moving around the folded paper under the nozzle. Alternatively, you could try installing an ABL (Auto Bed Leveling) sensor, such as a BLTouch, to automate this process. If leveling the bed didn’t help, you could try cleaning the bed with rubbing alcohol or IPA.

One other method would be coating the bed in an adhesive, such as hairspray or glue stick. Although this may sound silly, it effectively sticks the print to the bed, further increasing the bed adhesion. Dedicated products, such as Wolfbite, can also be used the same way.

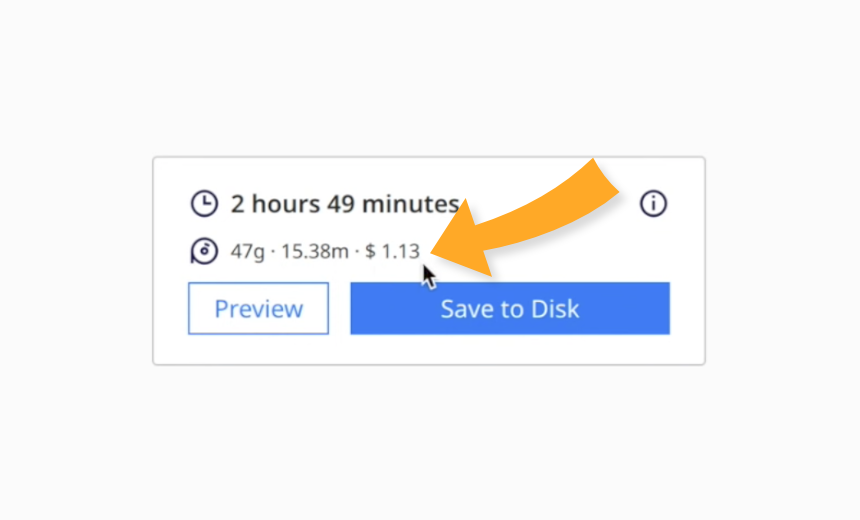

You can also try to improve bed adhesion within your slicer. Increasing your hotend and heated bed temperature can also help, ensuring that the plastic stays melted for a longer time, giving it more time to stick to the bed. It might be worth trying to turn down the part cooling fan speed during the first layer, further increasing the time the plastic stays molten. Additionally, you could use a printed aid such as a brim, which can increase the surface area between the print and the bed, or a raft - these create a large sacrificial platform below the print to offset it from the bed, meaning that the useful component of the print effectively has no bottom layer.