What is FDM 3D Printing?

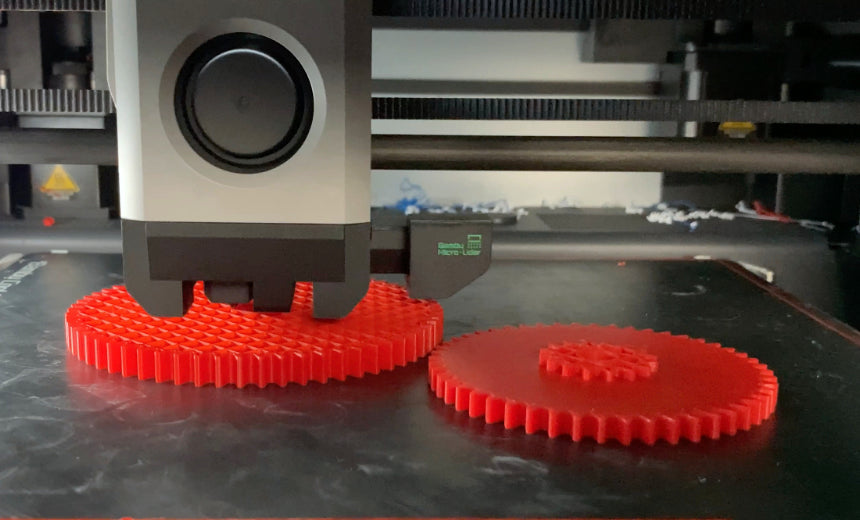

3D printing is the process of creating physical, three-dimensional objects, layer by layer. FDM stands for “fused deposition modeling.” With this process, an FDM 3D printer extrudes ‘molten’ plastic material out of a heated nozzle and lays down the material line-by-line and layer-by-layer. These deposited layers are fused together due to the high temperature of the extruded material. FDM and resin 3D printing both have their own benefits and drawbacks:

Pros of FDM 3D printing:

- Limited mess, easy set up, low toxicity, ease of use

Cons of FDM 3D printing:

- Low resolution / detail, weak parts

FDM 3D PRINTING PROCESS:

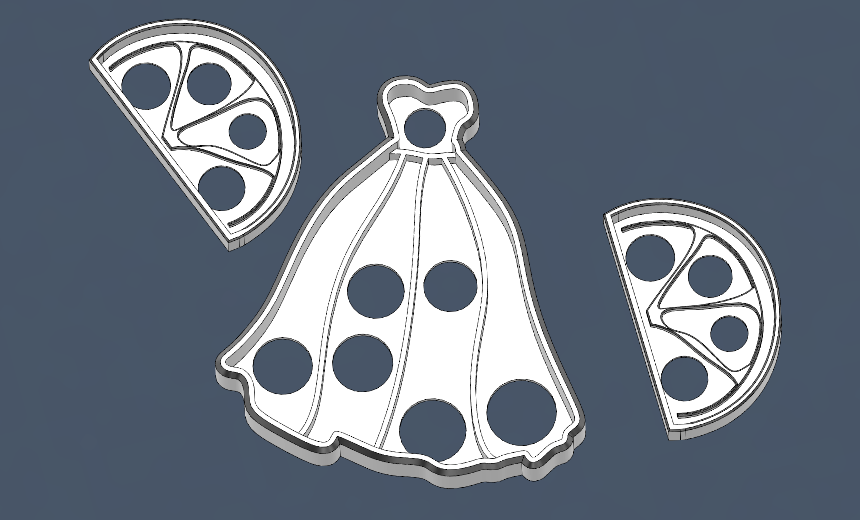

1. Start with an STL file:

Designs and 3D models are represented in the computer as STL files. You can download STL files from websites such as Thingiverse, Cults3D, MyMiniFactory, 3D Printer Academy, and others. Some websites have free STL files, while other are available to purchase. Alternatively, you can design your own 3D models using CAD or 3D modeling software such as Fusion 360, Blender, and many others.

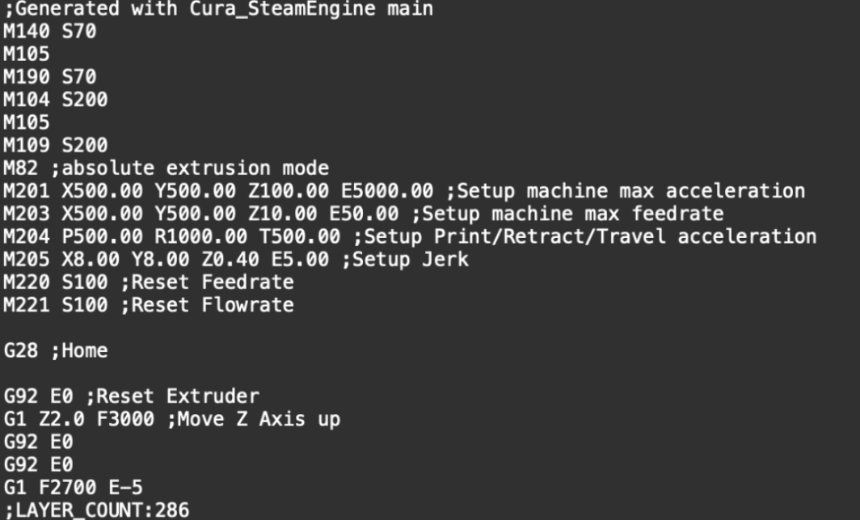

2. Import the STL file into a “slicer”

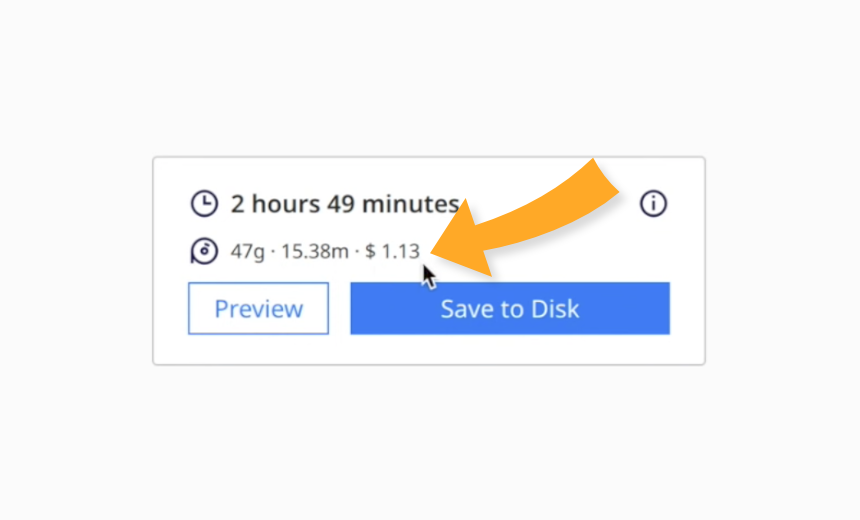

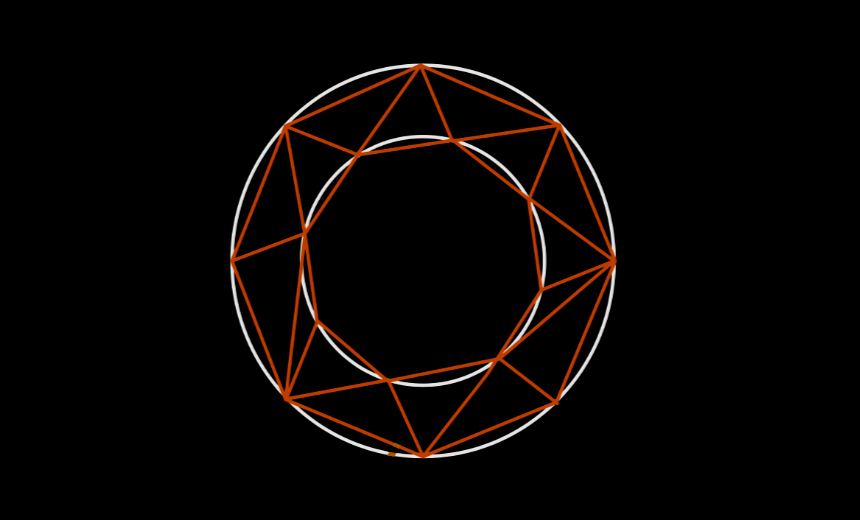

Slicers convert STL files into GCODE. 3D printers (and CNC machines) use GCODE to control their movement. One of the most popular slicers is Ultimaker Cura. It is free, open source, and is regularly updated. In the slicer program you can determine print settings such as layer height, infill, supports, bed adhesion, temperature, and many other configuration settings.

3. Export GCODE

Once you have determined the settings for your print, slice the 3D model. After slicing the 3D model, save the GCODE file to an SD card, or to your computer. Most 3D printers print directly from an SD card. You will most likely need an SD card adapter for your computer. Alternatively, you can 3D print wirelessly over your local wifi network using Octoprint.

4. Send File to 3D Printer and Print

(Some modern 3D printers, like Bambu Lab 3D printers, are connected to the internet and have their own proprietary slicer and cloud printing services the make the process very easy and convenient.)